3d resin printer prints are slightly warped

Cleaning 3D printer build plate with isopropyl alchol Source. Properly check the settings of your printer.

Resin Print Warping How To Design Models To Avoid It Ameralabs

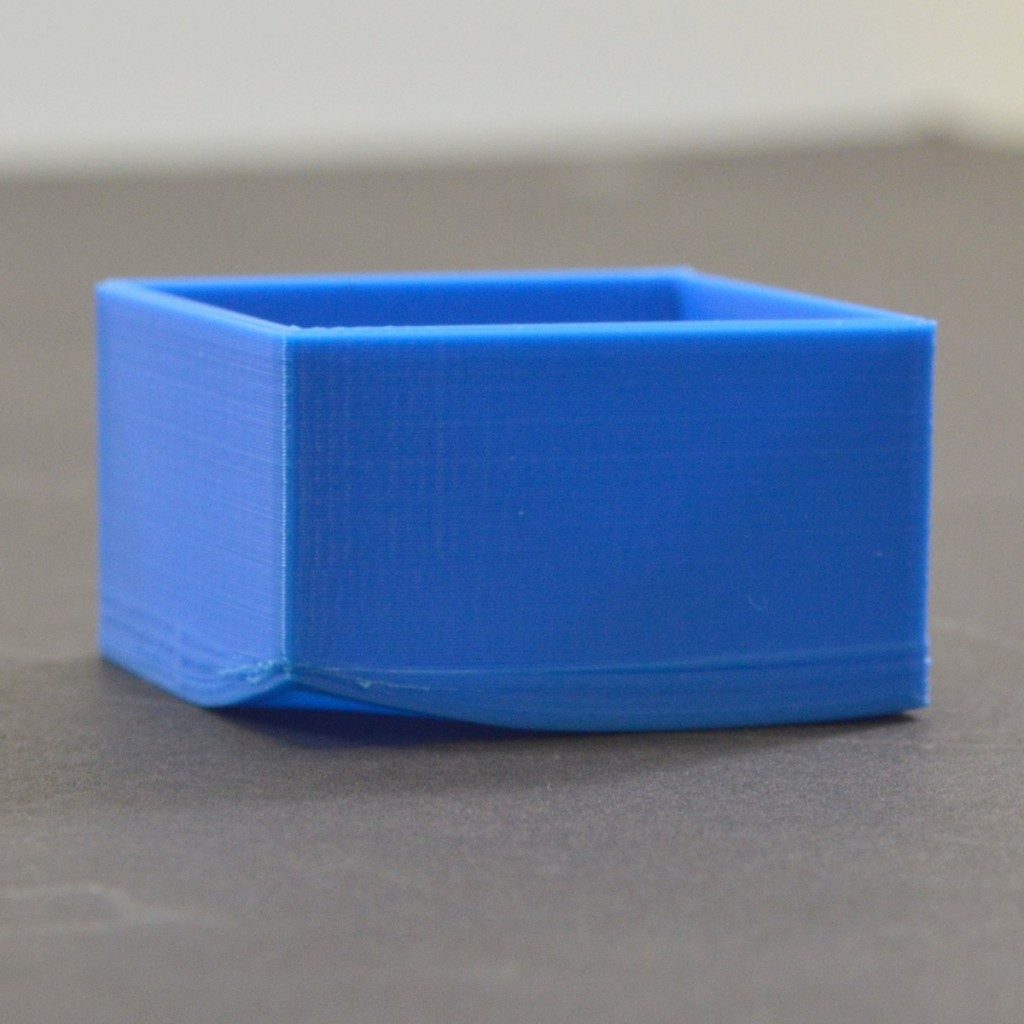

3D prints are warped Symptoms of warped 3D prints from 3D resin printers.

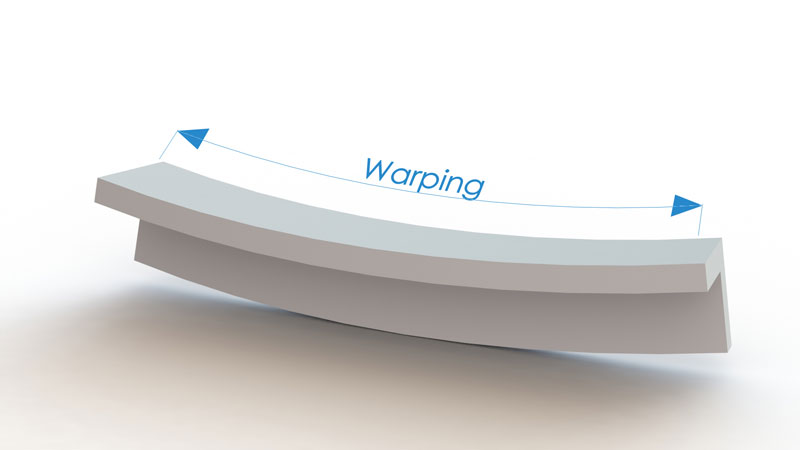

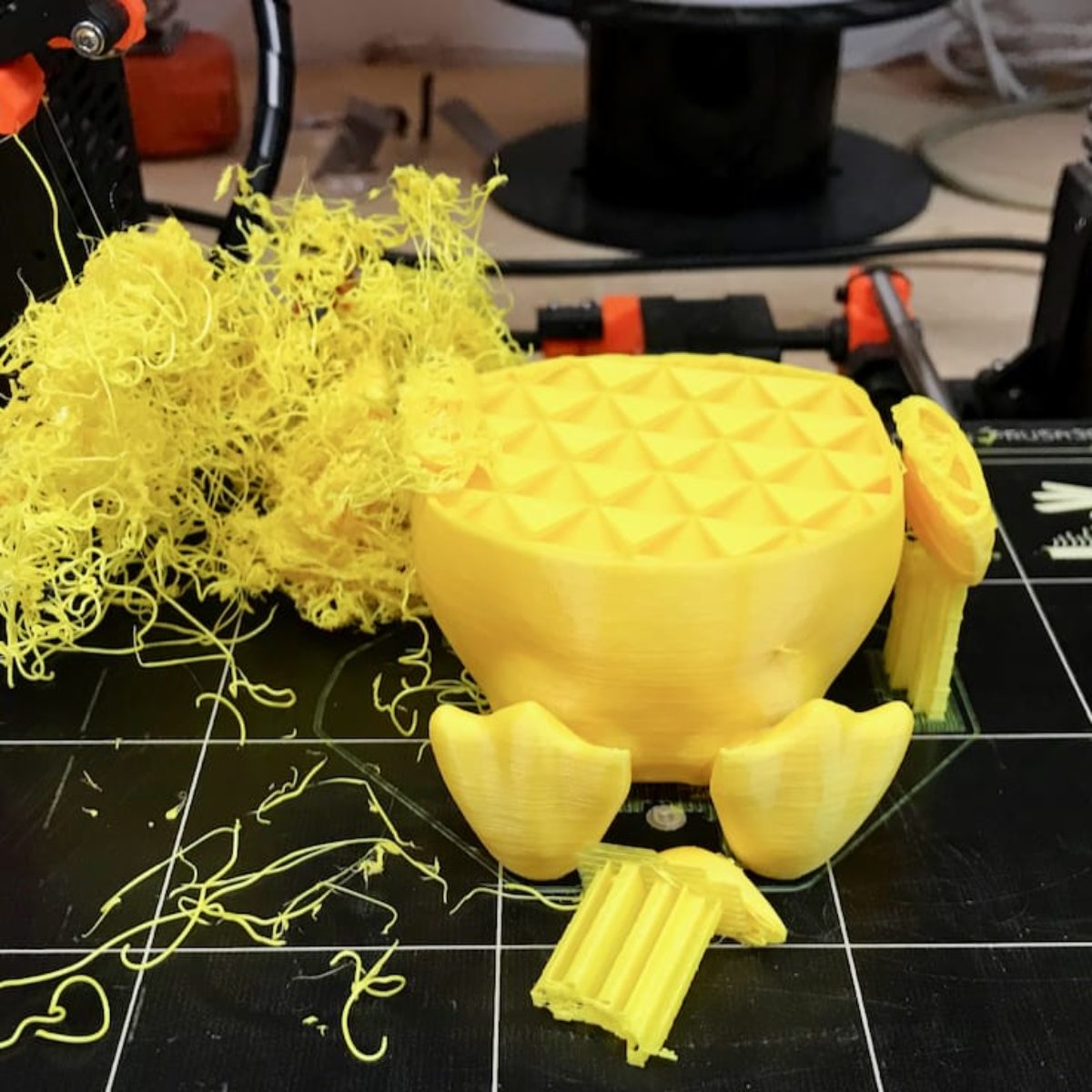

. Increase the support intersection. Warping is pretty obvious to diagnose. In 3D printing warping is where the bottom of a print starts to curl up at the edges.

Empty the resin vat and clean it very well with 95 IPA. Increase the support thickness. So if you do try that out for yourselves we.

The good news is that even though it can be caused for a number of reasons it is relatively simple to prevent. Waves are good for the beach but not for your 3D prints. Go on printing the rest of the frame around it.

And when I print on the plate its coming out short. Optimize the 3D slicer software settings. Apart from improving the quality of printing it reduces resin costs since a lesser quantity is used.

While this can be a relatively minor issue it can have catastrophic results for your print if it gets too bad. The less resin used the lower the model shrinkage and the lower the project cost. One of the first things youd want to do to fix support separation in your printing is to ensure that the diameter of your support tip is thick enough to hold your model.

Place the bucket upside down over the. Note the 3D printing prerequisites. Make sure the nozzles and base are clean before you start printing.

It is caused by wobbling either from the Z-axis or the print itself. Once the film is dry apply the lubricant very liberally on the film with a clean cloth being sure to get it into all the edges and corners. Peel the backing off the LED light strip and apply it to the inside of the bucket.

3D printer not extruding mid-print. If the part is still sticky rinse again with clean IPA and brush with a soft and maneuverable brush such as a toothbrush. This uncured resin continues to cure in the presence of ambient UV light that is all around us.

This will scrub. This is because the thicker your support tips are the more firm the supports will hold your model. Review the 3D model design.

3D Print Warping. Make Support Stronger in the Right Places. Every project and type of resin is different so check the configuration of your 3D printer when you start a new model.

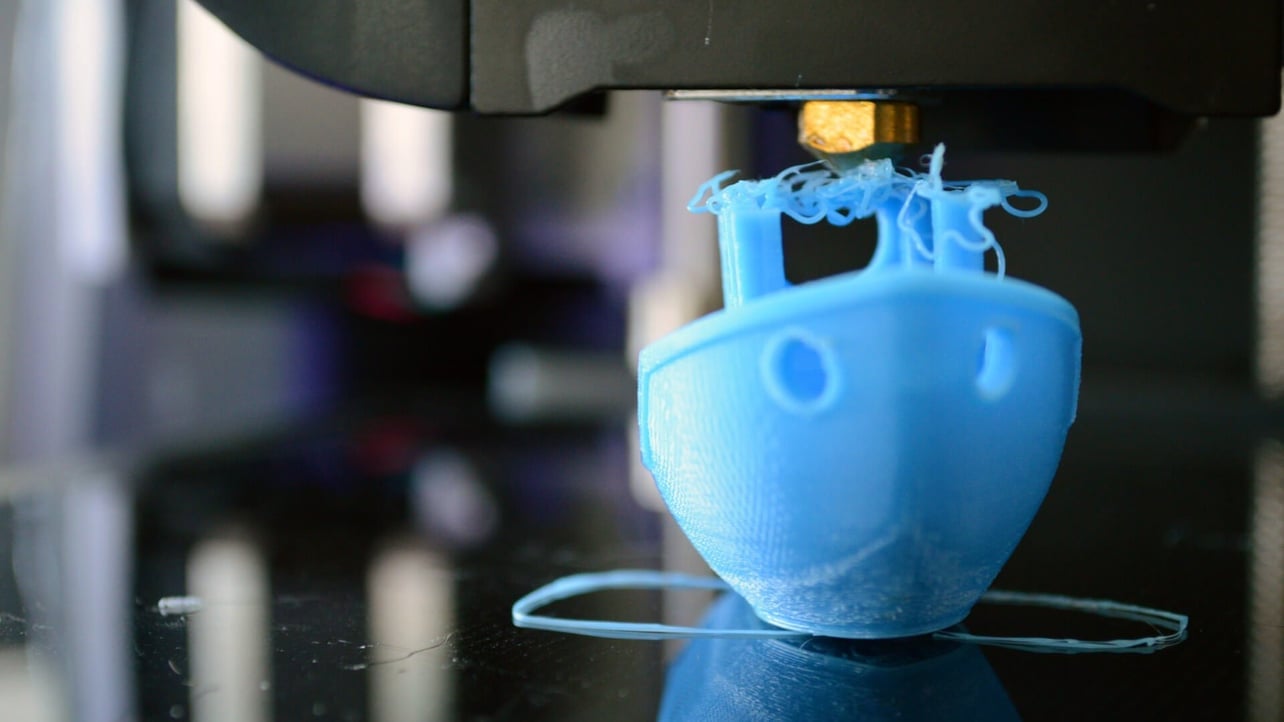

Adjust z-axis offsetor the nozzle height from the bed. If you find waves running up the entire height of the print or some layers are missing then you could be experiencing the most common 3D printing mistake. As we said warping is one of the most common problems that occurs when 3D printing.

Cover all sides and the top with the lights. Your print pops off the print bed mid-print and shifts or even topples. Allow the print to dry and see if the problem is solved.

Correct heated bed temperature. Clean the Build Plate And the Nozzle. The inevitable warped print has plagued me many times and I have finally found a way to lessen its devastation.

Increase the support tip thickness. This is not the case for warping effects. Issue 5.

Level your heated bed. Im using some bio pla from e sun. Ive just got my resin 3d printer and the prints are coming out warped or short.

Walk through these quick and easy steps to learn a practical way anyone with. Prepare the 3D resin printer. It is also worth mentioning that not all resin is cured right after 3D printing processAlthough we have solid object there is still uncured resin within the 3D printed part.

This is is a fairly simple process to do for fixing of broken resin 3d parts so that the long hours of 3d printing which went into them are not wasted. Control the 3D printers environment. Here are 6 preventive solutions to stop resin 3D prints from warping.

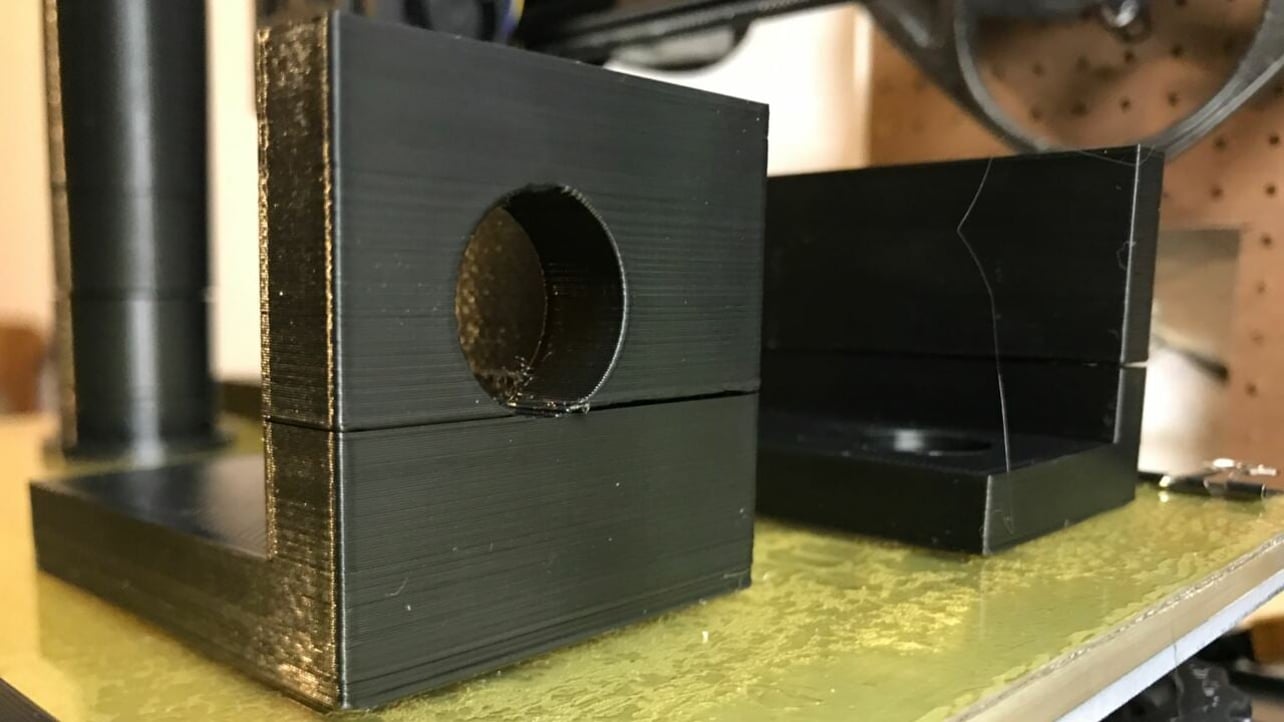

Sometimes the supports are nicely printed but the part is missing. So excuse poetic licence Im using with the image below its not a DLP print but it illustrates the point. When using supports the side where the supports are is totally distorted and uneven compared to the other side.

10 Quick And Easy Fix 1. Most likely the 3D printing surface of that layer is over-extruded or slightly warped or pillowed and thats why the nozzle scratched it in the move. Sometimes you can get warped edges or indeed warping in an entire part.

Ongoing curing can still cause cracks and warping which can be reduced if proper resin 3D print. In most cases this failure happens at the support tips. PTFE lubricant can also be used reduce the stickiness of the FEP fill.

This can definitely be applied also to assembles of models which had to be broken down into parts to fit smaller resin 3d printers. Some big some small some really warped some slightly warped. There are a few ways to fix this.

Some models are designed for resin based printers and will fail miserably on FDM filament based.

3d Printing Materials The Pros And Cons Of Each Type Tom S Guide

3d Printing Troubleshooting Guide Layer Separation Youtube

13 Ways How To Fix Resin 3d Print Supports That Fail Separation 3d Printerly

Designing For Printing Part 2 Why 3d Printed Parts Warp And How To

How To Fix Warping Ultimaker Support

Troubleshooting 3d Prints Fixing Warping And Cracking Youtube

Adhesion Resin Prints Pulling Away From Build Platform 3d Printing Stack Exchange

Resin Print Warping How To Design Models To Avoid It Ameralabs

3d Printing Troubleshooting Common 3d Printing Problems All3dp

Why Resin 3d Prints Fail Improve Your Prints Tips On Understanding Overhangs And Supports Youtube

Dlp 3d Printing Troubleshooting L3d

3d Printering Sticky Resin Prints And How To Fix Them Hackaday

3d Printer Troubleshooting Guide Warping Youtube

Any Reason For These Layer Lines I M New To Resin And This Is My Second Print After The Test Print From Anycubic S Website R Anycubicphoton

3d Print Layer Separation 8 Tips To Avoid Delamination All3dp

How To Persistent 3d Print Failure Here S What To Look For Fabbaloo

5 Reasons You Need A Hot Air Gun In Your 3d Printing Toolkit 2015 Youtube